- Back

- INTERNATIONAL OPERATIONS

- INTERNATIONAL OPERATIONS SCIENTIFIC AND TECHNOLOGICAL OPERATIONS

- BASE ORGANIZATION (BO) IN THE COMMONWEALTH OF INDEPENDENT STATES (CIS)

- CIS BASIC ORGANIZATION EVENTS

Radioactive waste management is one of the key lines of the integrator’s decommissioning activities.

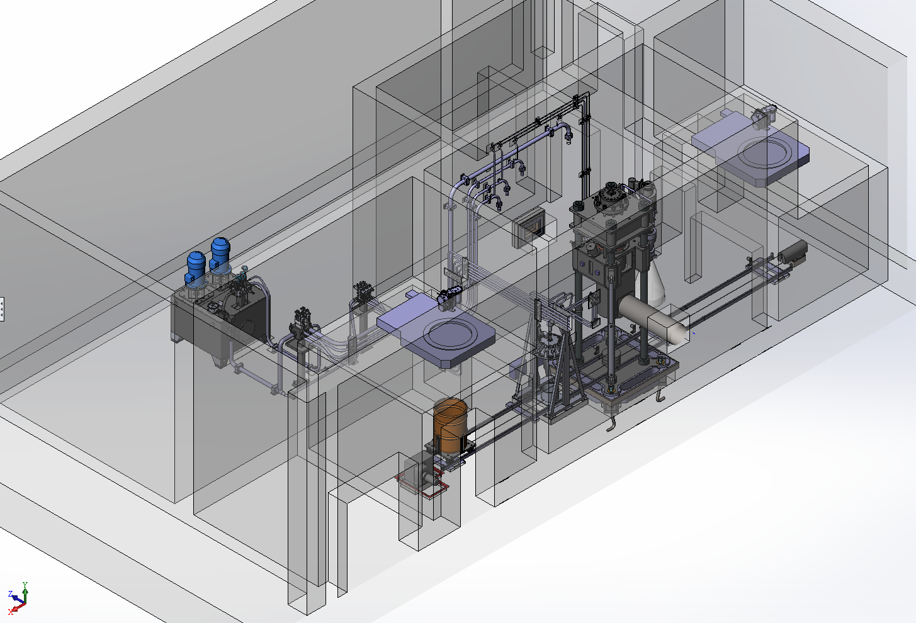

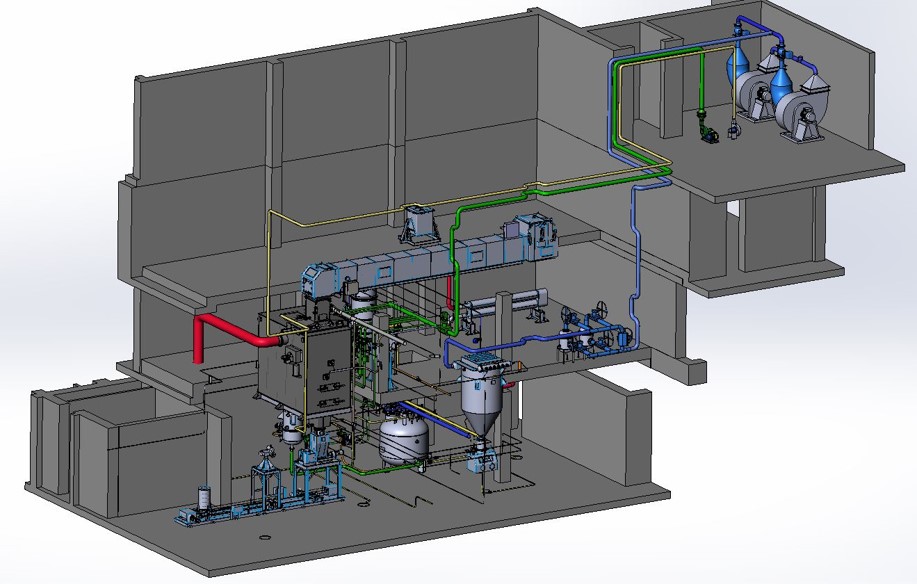

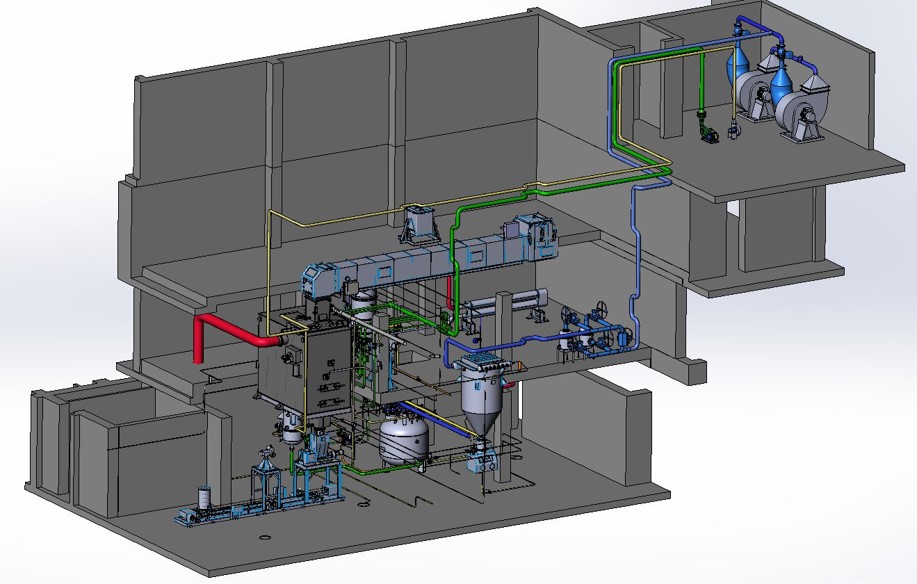

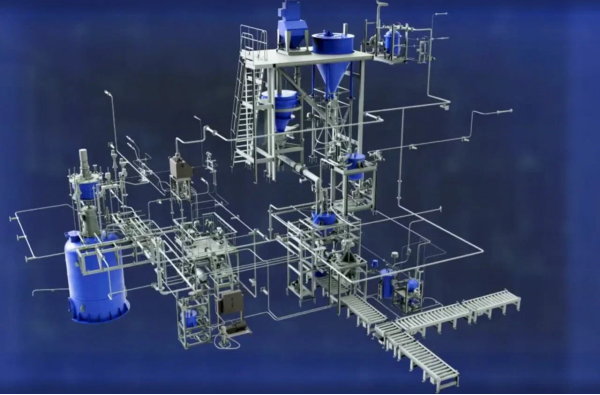

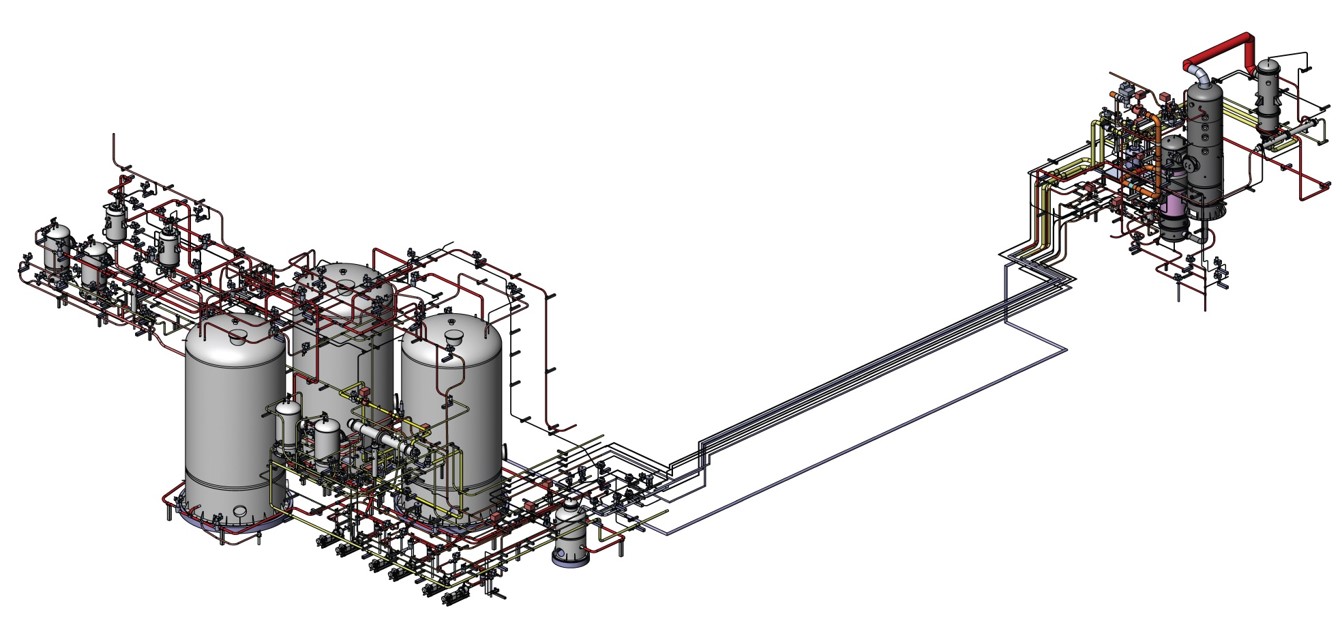

Our company provides services in technical consulting, design of infrastructure for RAW management, design and supply, as well as equipment upgrading.

The decommissioning integrator offers an extensive list of solutions for conditioning radioactive waste from nuclear power plants, radiochemical and other facilities. At the conditioning stage, RAW is converted into a form suitable for storage, processing and transportation and subsequent final containment. Besides, we process secondary RAW, which is generated as a result of radioactive waste management

The integrator has a broad line of products for processing solid and liquid radioactive waste, including RAW pressing, incinerating, cementing, vitrification, and waste evaporating and solidifying equipment.

We value your privacy

By continuing to use our site, you consent to the processing of cookies, which ensure its correct operation.